Paving stones have long been a popular building material for both landscaping (e.g., patios and pool decks) and industrial needs (e.g., roads). And because they are durable and come in a variety of options, pavers are an excellent choice for a multitude of hardscape projects.

Because of this variety, there are a multitude of factors you should consider when choosing a paver for your next project, including cost, durability, and aesthetic.

Today, we’ll take a deep dive into pavers so that you can make the decision that is right for your project.

Chapter 1: History of Pavers

"Via Appia Antica" by Stijn Nieuwendijk is licensed under CC BY 2.0

"Via Appia Antica" by Stijn Nieuwendijk is licensed under CC BY 2.0

The history of pavers is long and varied, dating back nearly 5,000 years.

The oldest paved road in the world was discovered in Giza, Egypt in 1994. By dating items found near the road, specifically pottery fragments and a camp for the ancient stone works, geologists have determined that this ancient road was built around 2600 to 2200 B.C.[1] During this time period (also known as the Old Kingdom), many quarries sprung up to fulfill the high demand for stones used in building pyramids and temples near the Nile River [2] and Egyptians paved the road (which measures 7.5 miles long and 6.5 feet wide) with thousands of slabs of sandstone and limestone as a way to facilitate movement of these heavy building stones.

But the ancient Egyptians weren’t the only early civilization to make use of paved roads. Perhaps more famously, the ancient Romans relied heavily on paved roads to travel and rule their large empire. Of the many early Roman roads, the oldest (and most famous) is Via Appia, or the Appian Way. Begun in 312 B.C., this ancient road stretched 362 miles from Rome to Brindisi in the southeastern portion of Italy by the time it was completed in 244 B.C. Still in existence today, the road’s longevity can be attributed to its superior building method, including use of paving stones. Roman road were constructed by first laying a foundation of heavy stone blocks cemented together with lime mortar, over which were polygonal blocks of lava. These smooth and expertly fit together blocks formed a strong and durable traveling surface that aided the Roman army in traveling throughout the empire.[3]

Paving stones have continued to be highly utilized in road building applications, with clay pavers, cobblestones, and Belgian blocks lining the streets of the United States and European countries for hundreds of years.

In more modern times, paving stones once again rose to prominence as a popular building material when the Dutch replaced clay brick streets damaged during World War II with concrete pavers.[4] The adoption of concrete pavers as a solid building choice continued to grow in Europe throughout the 1960s and 1970s, as well as North America, where the paving industry has grown rapidly, from nearly 80 million square feet in 1980 to over 755 million square feet in 2005.[5]

Chapter 2: Natural Stone

"Flagstones" by Bruce Washburn is licensed under CC BY 2.0

"Flagstones" by Bruce Washburn is licensed under CC BY 2.0

Of the 5 main paving stone choices, natural stone is the oldest variety. In ancient times, stones such as sandstone, limestone, and lava blocks were favored. Since then, bluestone, travertine, flagstone, and limestone have risen to the top as the most common varieties of natural stone pavers.

Manufacturing Process

Natural stone pavers are manufactured by first mining the stone in a quarry. The quarried stones are cut into large blocks and removed from the quarry. Next, these blocks are cut into smaller pavers, slabs, or tiles before being polished to its desired finish.

Cost

Because of the specialized and intensive process it takes to produce natural stone pavers, they tend to be among the pricier of the paving stone options available. Bear in mind that the price of using a natural stone paver will vary based on a few options.

The specific type of stone plays a huge factor in cost. Lower priced stones, such as Pinola, will run around $295 per ton with higher priced stones, such as Canyon Gold Quartzite, coming in at a whopping $700 - $900 per ton.[6]

Cost is also influenced by the specific look you want to achieve. If you’re looking for a more uniform look, expect to pay more.

Durability

As the ancient Egyptian and Roman roads show, natural stone is highly durable. When tested, most natural stones have a high compressive strength, though results will vary based on where the stone is quarried.

Despite their strength, most natural stones are porous, which leads to high water absorption. While this is beneficial around a pool, it also makes natural stones more prone to quick build up of both mold and algae. Because of this, regular cleaning and maintenance is a must.

Aesthetics

Natural stone provides the most organic and varied look of the common paving stones. This organic look is achieved by the variety of colors, shapes, and thicknesses that may be included in a pallet of natural stone.

It is possible to achieve a more uniform look (both in color and size) with natural stones, but as mentioned above, doing so comes with a higher price tag.

Summary

Natural stone is a beautiful, durable option for your hardscape. However, expect it to come with a relatively high cost and intensive maintenance demands.

Chapter 3: Clay Pavers (Clay Brick)

"walkway" by John Hildreth is licensed under CC BY 2.0

"walkway" by John Hildreth is licensed under CC BY 2.0

Like natural stone, clay pavers have been a popular hardscape choice for centuries. In fact, they were the first mass-produced pavers, replacing cobblestones and hand hewn bricks.

Manufacturing Process

As the name implies, clay bricks are made from clay, with the best brick composition being somewhere around:

- Silica (50 to 60%)

- Alumina (20 to 30%)

- Lime (2 to 5%)

- Oxide of Iron (5 to 6%, ≤7%)

- Magnesia (<1%) [7]

The clay is formed into brick shapes and then hard-fired in kilns. This firing process allows the clay particles to fuse and strengthen.

Cost

Clay pavers are the most expensive of the 5 common paving stone varieties. In fact, you can expect to pay 15% to 20% more for a clay paver than a similar looking concrete paver. This cost differential comes down to the expense of the raw materials. The clay that goes into clay pavers is more expensive than the aggregates used to make concrete pavers.

Durability

Though clay pavers may cost more than other paver options, you can expect the cost differential to made up in durability, with clay pavers being one of the most durable options on the market. Though they may chip or crack over time, they last for generations.

Clay pavers really shine when it comes to color retention and low maintenance. Because clay pavers are naturally colored by the clay particulates they’re comprised of, they display a high color retention, meaning the pavers you install today won’t be faded in a year’s time. Furthermore, clay bricks tend to be less porous than other options, so they resist staining, as well as mold and algae build up, making them a low maintenance choice.

Aesthetics

Clay pavers are great for achieving a consistent look, and as mentioned above, they will retain their color for years to come. However, the tradeoff is that there are fewer varieties. Due to their color being derived from clay particulates, clay pavers are limited in their color choices. Furthermore, they typically only come in rectangle (or brick) shapes, and are available in only a few sizes.

Because of this, clay pavers are a great choice if you want a consistent look, but if you’re wanting something more outside of the box, you’ll want to choose a different option.

Summary

Clay pavers are a great choice if you’re looking for a durable material to build a uniformly patterned hardscape. However, due to the manufacturing process, expect to pay more for clay pavers than you would pay for any other paving stone.

Chapter 4: Reclaimed Clay Pavers

"Old Brick Road" by Jim Grey is licensed under CC BY 2.0

"Old Brick Road" by Jim Grey is licensed under CC BY 2.0

Reclaimed clay pavers combine the allure of using reclaimed materials with the thrill of creating something new. Not only does choosing a reclaimed clay paver add character to your project, but it is also a “green” option because it simply reuses an item that has already been made.

Manufacturing Process

Like the name implies, reclaimed clay pavers are simply clay pavers that have been salvaged from abandoned buildings, houses, roads and railyards. Typically, reclaimed clay pavers are bricks that were made by hand in the 1800s, as they were most popular during this time period.

Cost

Reclaimed clay pavers tend to sit around or just under the same price point as new clay pavers. However, as with all antiques, the cost of the brick is driven largely by its rarity – the more common the brick, the less expensive; the rarer the brick, the more expensive.

Durability

Though modern day clay pavers are some of the most durable paver options on the market, the same does not hold true for reclaimed clay pavers. In fact, reclaimed clay pavers are considered “fragile” by today’s standards, and are far less durable than any of the other paving stone options available. Furthermore, due to the recycled nature of reclaimed pavers, they require much more maintenance than new clay pavers.

Aesthetics

The aesthetic appeal of reclaimed clay pavers is a driving force behind its popularity. Whether you’re wanting a paving material to complement an older home, or you want to harness the character that can only be found with reclaimed products, reclaimed clay pavers are perfect for attaining a weathered or antique look.

However, because the bricks are reclaimed, they are not uniform, and with different manufacturing standards, they can also vary in dimension on all sides. Because of this, these pavers are harder to lay, and tend to give a less uniform look than new clay pavers.

Summary

If you’re looking for a material that is both unique and adds character to a hardscape, reclaimed clay pavers are the perfect fit for your project. However, what you gain in character, you lose in both durability and cost efficiency. Unless you want the specific look of reclaimed brick, go with the durability of a new clay paver or the cost efficiency of a concrete paver (either dry cast or wet cast).

Chapter 5: Dry Cast Concrete Pavers

"victorian-6" by Rochester Concrete Products is licensed under CC BY 2.0

"victorian-6" by Rochester Concrete Products is licensed under CC BY 2.0

Dry cast concrete pavers are the most popular paving stone on the market. They’re typically what people think of when they think of pavers. And for good reason – their moderate durability and their low cost of entry make it a reasonable compromise.

Manufacturing Process

The main distinguishing factor of dry cast concrete pavers is the low water-to-cement ratio used when manufacturing the paver. The water ratio is so low that the material is nearly dry, hence the name “dry cast” pavers.

A mix of sand, cement, and other aggregates, is put in paving molds and hydraulically pressed and pulsed using heavy machinery. Because of the low water-to-cement ratio, these pavers are able to be removed from their molds immediately after formation, and allowed to air cure.

Cost

Because of the manufacturing process, dry cast concrete pavers are easy and affordable to produce. Specifically, the ability to cure the pavers outside of the molds makes production more efficient, because molds are not tied up waiting for the pavers to cure.

Of all of the paver options, dry cast concrete pavers are the most affordable and are typically available in garden centers and big box stores, like Home Depot or Lowes.

Durability

Dry cast concrete pavers are dense, and therefore have a high compressive strength, average around 8,000 psi. This high compressive strength means they are less prone to chipping or cracking.

Despite their strength, dry cast concrete pavers have poor color retention and tend to lose their color or fade faster than other options. This tendency to fade is due to its composition – sand, which is the main component of dry cast pavers, does not absorb dies or paints.

Aesthetics

Like most mass-produced items, dry cast concrete pavers tend to be a bit less refined than some of the pricier options available. In general, dry cast pavers tend to have rough surfaces, rounded edges, and a dull finish. This lackluster finish is due mainly to the manufacturing process.

Summary

Dry cast pavers are a great solution if you’re wanting a paver that is both durable and sticks to a budget. However, be aware that with the cheaper price tag comes a compromise – you won’t get the refined finishes you can get with other paver options.

Chapter 6: Wet Cast Concrete Pavers

FireRock Wet Cast Concrete Pavers in Steel

Wet cast concrete pavers are the newest paver option on the market. Though they were first poured in mass in the 1990s in Germany, wet cast manufacturing didn’t really being in the United States until the early 2000s. Since then, the wet cast concrete paver industry has grown quickly in popularity.

Manufacturing Process

Wet cast concrete pavers are manufactured using a higher water-to-cement ratio than dry cast pavers. With wet cast pavers, a slurry of concrete, water, and other aggregates are poured into a mold, where they are smoothed into the mold (often by hand) before being allowed to cure.

Unlike their dry cast counterparts, wet cast pavers are left to cure before removing them from their molds, which makes the overall production time longer.

Cost

Because of the lengthened production time that is inherent in manufacturing wet cast pavers, the cost is higher than dry cast pavers. Typically, prices for wet cast pavers are comparable to that of natural stone. However, unlike natural stone, wet cast pavers offer the consistent quality of a manufactured product, so you won’t have to pay more for a uniform pattern or color.

Durability

Wet cast pavers are both durable and have fabulous color retention. Though they have less compressive strength than dry cast pavers, wet cast pavers are still moderately strong, with an average compressive strength of 6,500 psi. And some wet cast pavers, like FireRock’s concrete pavers, which has a compressive strength of 7,928 psi, nearly match the strength of dry cast pavers.

Though wet cast pavers are slightly less strong than their dry counterparts, they feature a much-improved color retention. The paver’s color is mixed into the slurry during the manufacturing process, meaning that the color of the paver is part of its chemical composition. Due to this, they are less susceptible to fading.

Aesthetics

Wet cast pavers are often characterized by veining or pitting techniques, which are designed to mimic the organic texture of natural stone. Because of this, wet cast pavers are sometimes used as a substitute for natural stone. With wet cast pavers, you get the added benefit of being able to achieve uniform colors and patterns that aren’t always possible with natural stone.

Though veining and pitting is popular on most wet cast pavers, smoother finishes and brighter colors are also possible.

Summary

If you’re wanting a paver that has a refined finished without the high price tag of a clay paver or the non-uniformity of natural stone, wet cast pavers are a great middle ground. With textures that mimic natural stone and the consistent quality of a manufactured product, wet cast pavers add beauty and refinement to any hardscape project.

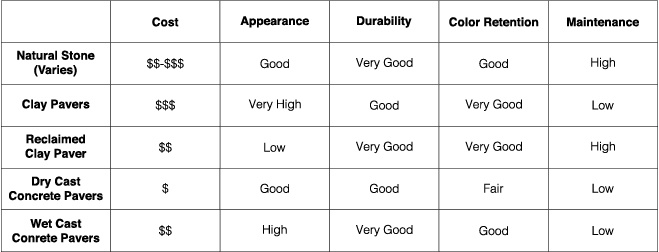

Chapter 7: Comparison Chart

So now you know the nitty gritty of the differences among the 5 main paving stone options on the market today. When making your final decision, don’t let one factor make the decision for you. Any good hardscape project will balance the cost, durability, and aesthetic of the material.

Footnotes

[1] John Noble Wilford. “World's Oldest Paved Road Found in Egypt,” New York Times, May 8, 1994, https://www.nytimes.com/1994/05/08/world/world-s-oldest-paved-road-found-in-egypt.html

[2] John Noble Wilford. “World's Oldest Paved Road Found in Egypt,” New York Times, May 8, 1994, https://www.nytimes.com/1994/05/08/world/world-s-oldest-paved-road-found-in-egypt.html

[3] “Appian Way,” Encyclopaedia Brittanica, last modified September 19, 2017, https://www.britannica.com/topic/Appian-Way

[4] “Our Industry,” Interlocking Concrete Pavement Institute, https://www.icpi.org/about/our-industry

[5] “Our Industry,” Interlocking Concrete Pavement Institute, https://www.icpi.org/about/our-industry

[6] “Flagstone Price Guide,” Home Advisor, https://www.homeadvisor.com/cost/outdoor-living/flagstone-prices-install-costs/

[7] Dr. B.C. Punmia, Basic Civil Engineering (New Delhi: Laxmi Publications, 2004), 33.