When it comes to indoor or outdoor flooring pavers, the options can seem endless. Like we discussed before with patterns, pavers are available in a wide variety of materials, colors, shapes, thicknesses, layout sizes, etc. The abundance of choices can quickly become overwhelming for any new construction, renovation or DIY project.

Remember: Knowledge is power! Learning the important fundamentals of pavers can help simplify your decision-making process AND your overall project.

This article will teach you the need-to-know basic facts about natural stone and cast stone, the most common type of indoor and outdoor flooring pavers.

Natural stone is one of the oldest building materials we still use today. In fact, one of the first instances of natural stone flooring dates back to Egypt. Pharaoh Djoser’s pyramid was made entirely out of natural stone and built to last into the afterlife. This structure set the precedent of using natural stone for pyramids and other sacred structures. [Image: Charlesjsharp for Wikipedia (CC BY-SA 3.0)]

When it comes to natural stone flooring, there are 3 types of rocks from which we carve:

It’s important to know the difference in rock types when deciding which natural stone to use for your project/application. Thankfully, you don't need a geologist to help you choose - all you need is data! Here are the most commonly used types of natural stone in architecture today.

But, out of these top five - granite, marble, slate, limestone and travertine - can you guess which one is used the MOST in modern architecture? Answer: Travertine

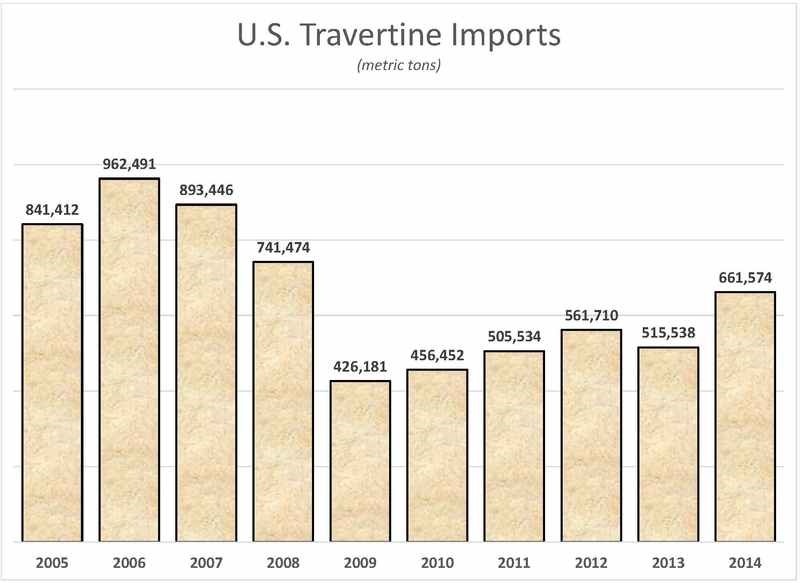

Travertine was the natural stone of choice by the Romans and was used to build many of their temples and even used in their greatest achievement – the Colosseum. Today, travertine still reigns supreme as one of the most frequently used natural stones. This is based on the number of metric tons imported into the US per year and then sold as reported by the U.S. Department of Commerce, the U.S. Treasury and the U.S. International Trade Commission. [Image: Stone Update]

But how does travertine remain one of the most popular natural stones? A few facts:

The earliest known use of cast stone dates back to medieval Europe where it was used to build fortresses, such as Cité de Carcassonne in France. Cast stone is a manufactured product that is designed to be a replicable alternative to natural stone. Cast stone can be engineered to simulate natural stone, or even reinforced with steel to be integrally stronger. [Image: bmsgator for Wikipedia (CC BY-SA 3.0)]

Two methods are used to create cast stone, which means TWO products fall into its category - "dry cast" and "wet cast." The biggest difference between them is the water-to-cement ratio. This ratio mix is a key factor because it determines which manufacturing processes are used, as well as the end-product's final appearance and durability.

According to the Cast Stone Institute, dry cast was first extensively used in London at the turn of the 20th century. By 1920, America caught on to the trend. Mass quantities were produced and used at this time. In fact, the whole manufacturing process behind dry cast pavers is designed to produce large quantities.

Dry cast pavers are made with a very dry mix of gravel, sand, cement and aggregate (for color). The mixture is poured into paver molds then hydraulically pressed and vibrated in the mold. By using a dry or zero slump mix, dry cast pavers are quick and easy to produce, plus molds can be immediately removed and re-used.

As for wet-cast stone, they are designed specifically to be a replica of natural stone. The first wide use of wet cast pavers was spotted in Europe in the ‘90s as an alternative to natural stone. Today, the demand for wet-cast stone has crossed international borders. Market data shows that the key non-European areas of demand are the United States, China, New Zealand and the United Arab Emirates.

Wet-cast pavers are made with a similar mixture to dry cast, but of course, water is added. Besides the aggregate that’s added for color, “veining” can be used to mimic the veins of minerals found in slabs of natural stone.

One way this is achieved is by placing strings that have been soaked in dye within the mold before it sets. Once the dye has had a chance to soak into the mixture, the mold will set and cure.

With so many new advances in manufacturing technology and global distribution, it’s important to remember the paver fundamentals that have guided homeowners (and emperors!) for centuries. Understanding more about the basic facts of natural stone and cast stone, such as material composition and product background, will arm you with confidence to make the best decision for your project.

Sources: