Firebrick + Adhesive Mortar

Customize your fireplace with an array of firebrick colors and sizes.

High-Quality Firebrick

Create a timeless, fire-resistant backsplash for your fireplace with an assortment of brick sizes and colors, ready to be placed in the pattern of your choice.

Feature one

Compliant with ASTM standards C1261, C27, and NFPA-211

Feature two

Meets international fireplace and chimney construction building codes

Specially-Formulated Adhesive Mortar

FireRock’s adhesive mortar is a low sand polymer modified with heat-resistant additives designed to work as a “glue” rather than a joint provider. This ensures your fireplace stays strong for the lifetime of your home build.

- Mortar for masonry chimney block must be purchased separately

- One bag of mortar is needed for every six masonry chimney pieces

- The necessary number of bags for each fireplace are included with the installation kit

- Weight per bag = 25 lbs; bags per pallet = 96 bags

Note: This mortar must be used to install the firebox in order for the FireRock warranty to be valid. It can also be used to install the firebrick, though substitutions are allowed.

How to Use FireRock

Adhesive Mortar

STEP 1

Mix the Mortar

Mix FireRick Adhesive Mortar with clean water (do not use spirits or anti-freeze agents according to the instructions on the bag until it reaches a “toothpaste” consistency, free of lumps or dry pockets. To ensure maximum strength, ensure it is not too thin or runny.

Do not apply the mortar if temperatures are below 40° F or will be within the 24 hours after application.

Do not apply the mortar if temperatures are below 40° F or will be within the 24 hours after application.

STEP 2

Apply Mortar

Use a trowel or grout bag to apply the mortar to the firebox and smoke chamber joints. Joints should be completely covered by ½”-1” of mortar, with the components stacked so as to result in a 1/16” to ⅛” joint. Any excess mortar should push (ooze) out and be scraped away.

Under normal conditions, assembly can be expected to cure in 24-48 hours.

Under normal conditions, assembly can be expected to cure in 24-48 hours.

STEP 3

Butter the Joints

At each level of the firebox, smoke chamber, and masonry chimney, it is important to go back and “butter” all joints. This procedure smoothes any excess mortar, both inside and out, and seals all joints, ensuring a “no leak” installation.

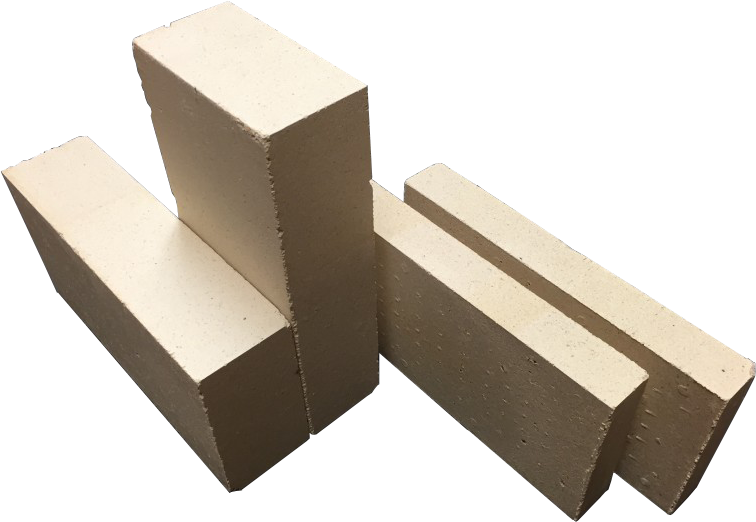

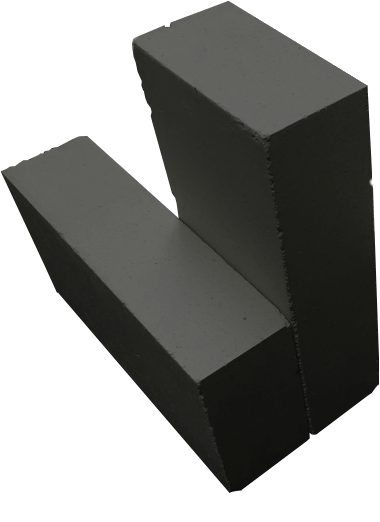

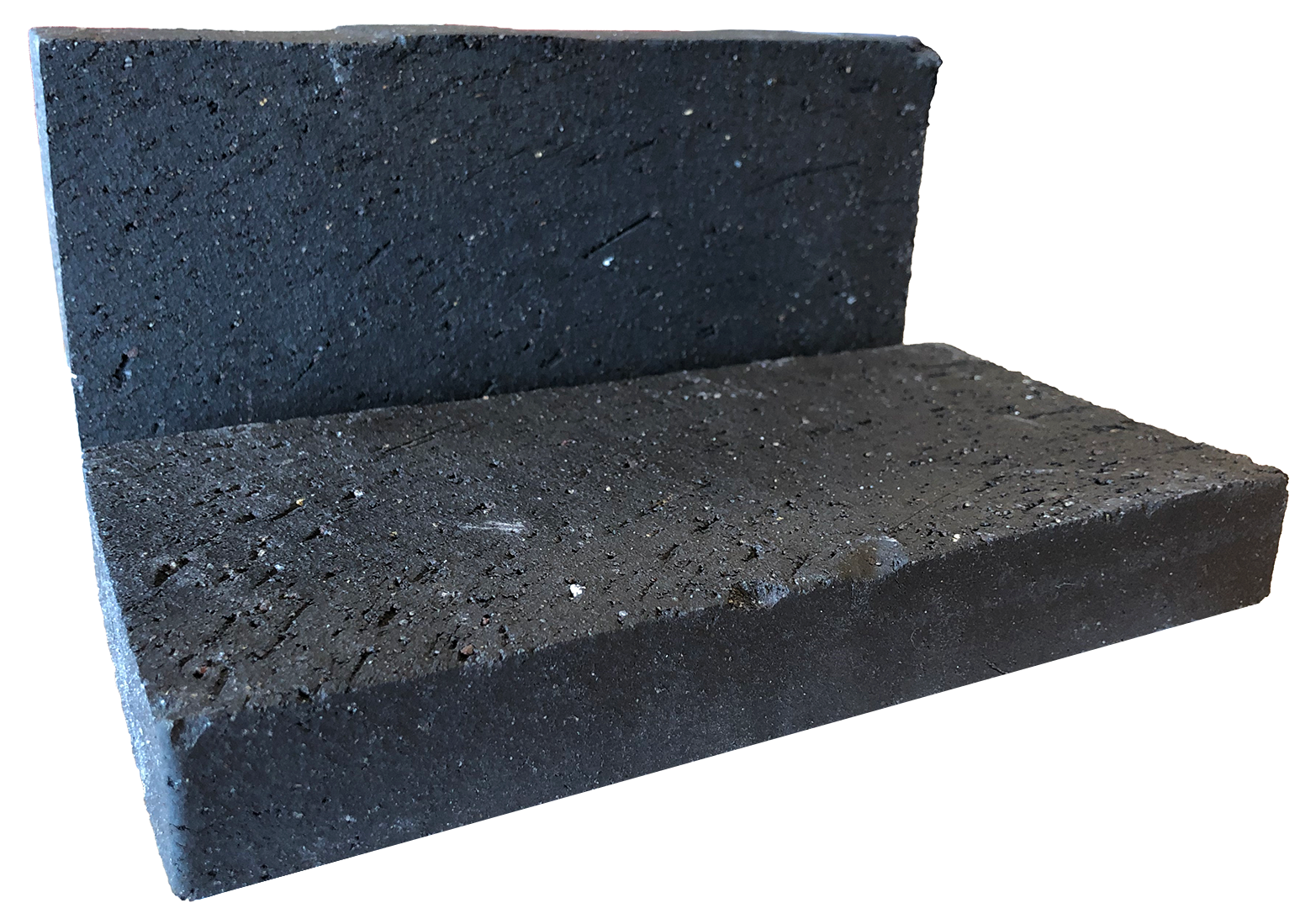

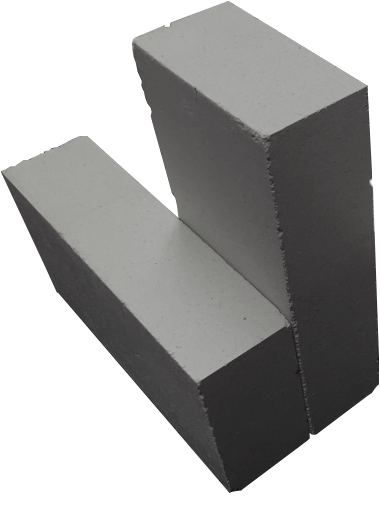

Colors

Buff

Red

Black (Glazed)

Black (Unglazed)

Slate Gray (Glazed)

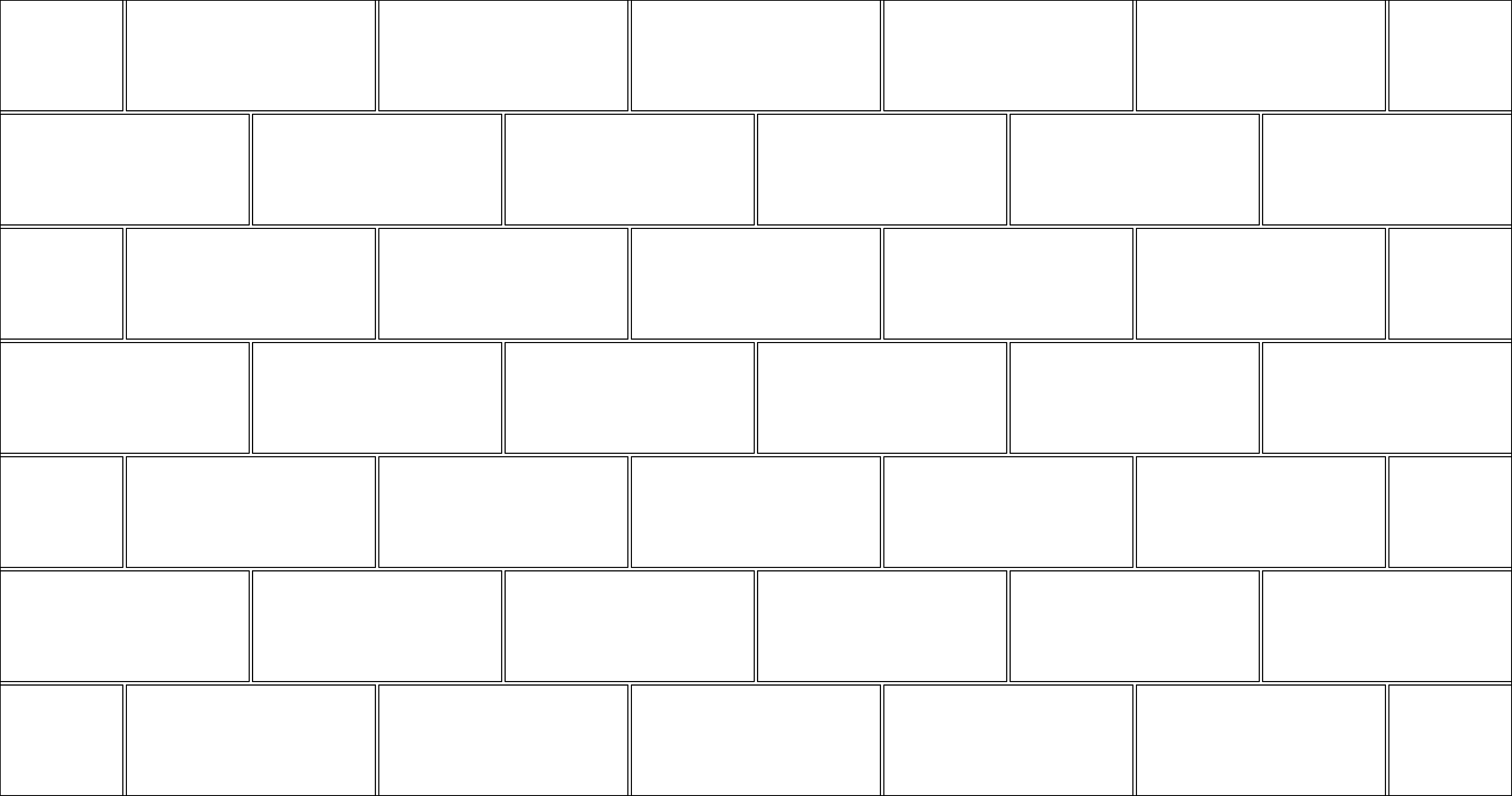

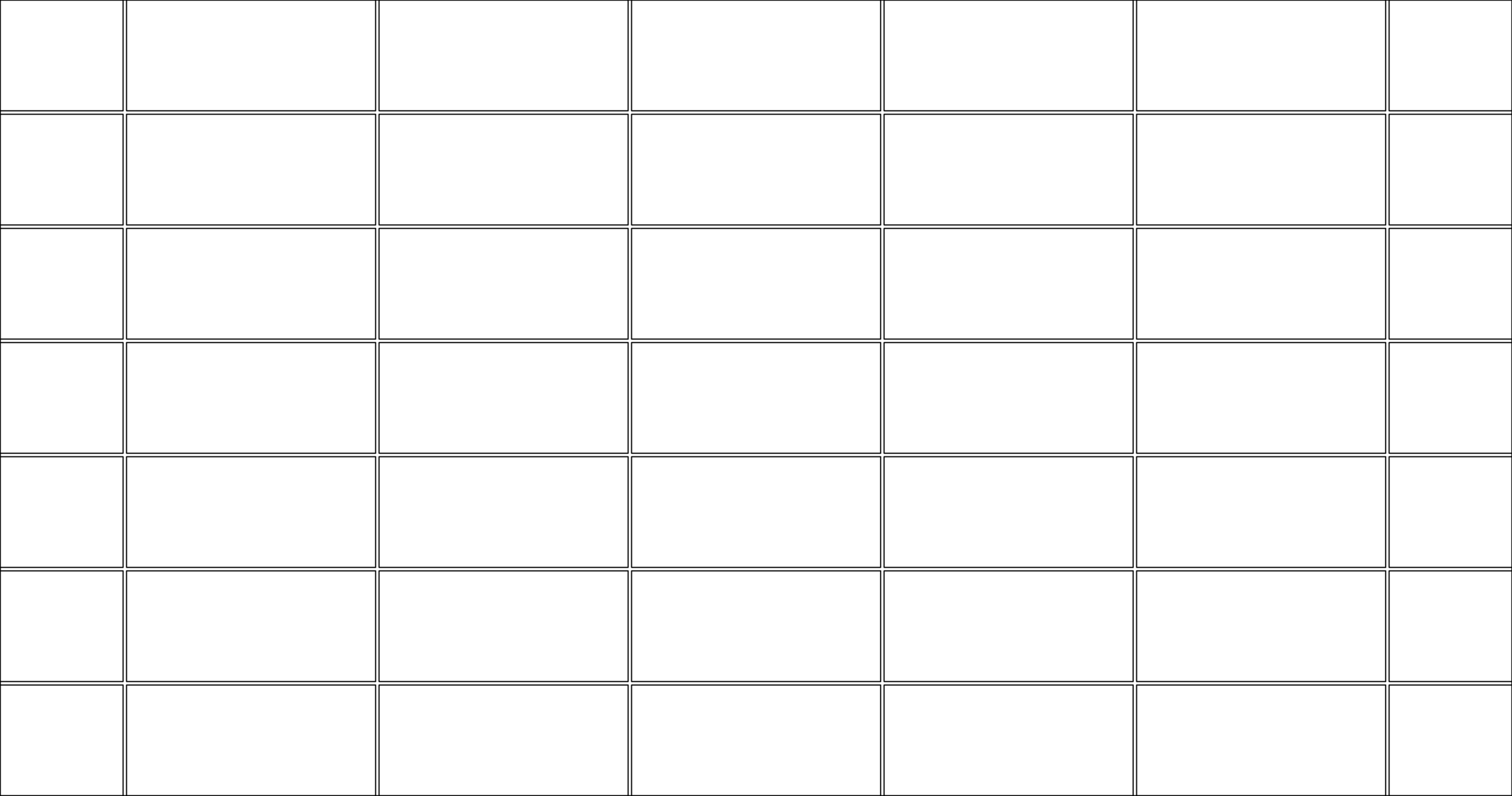

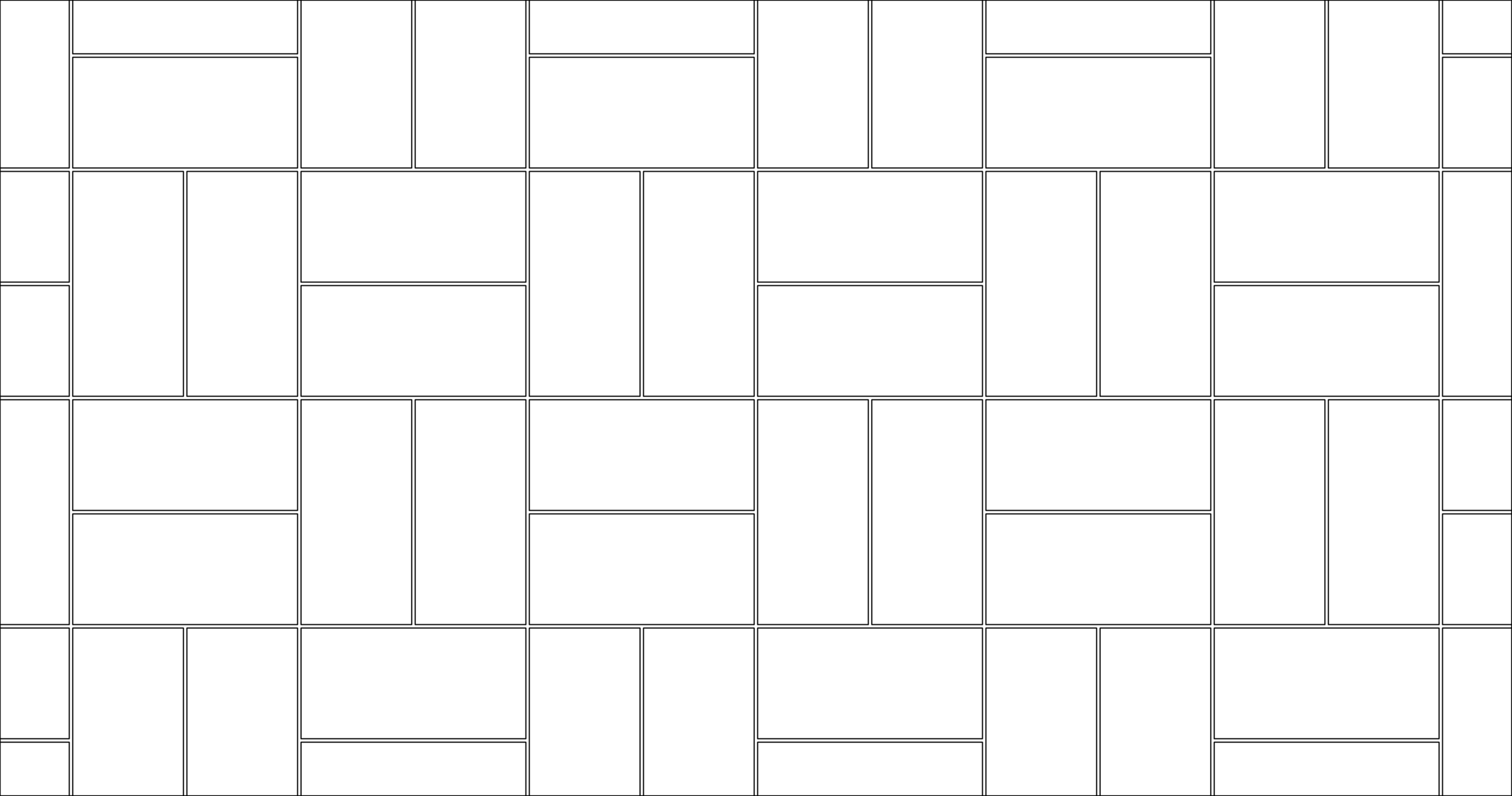

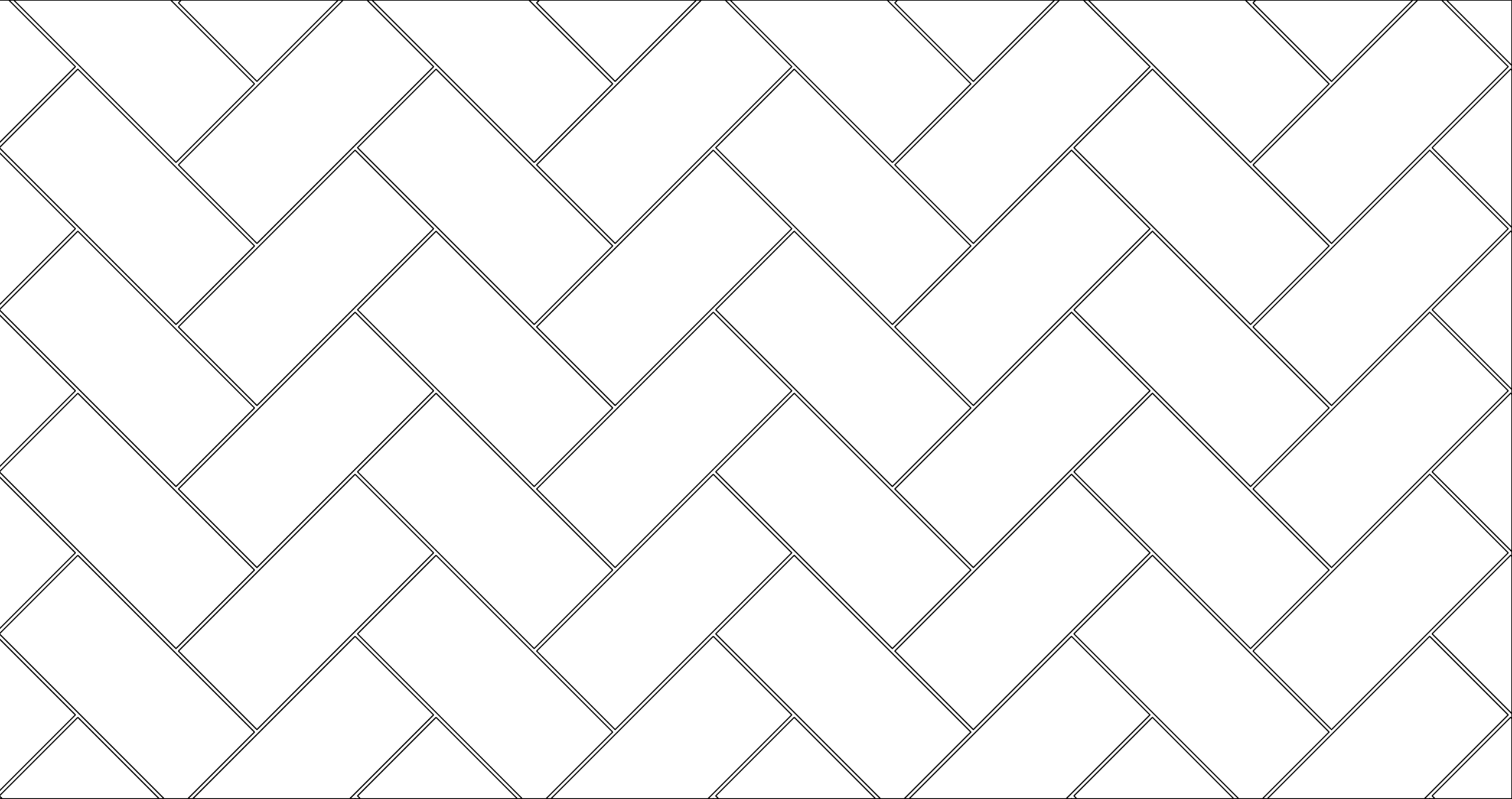

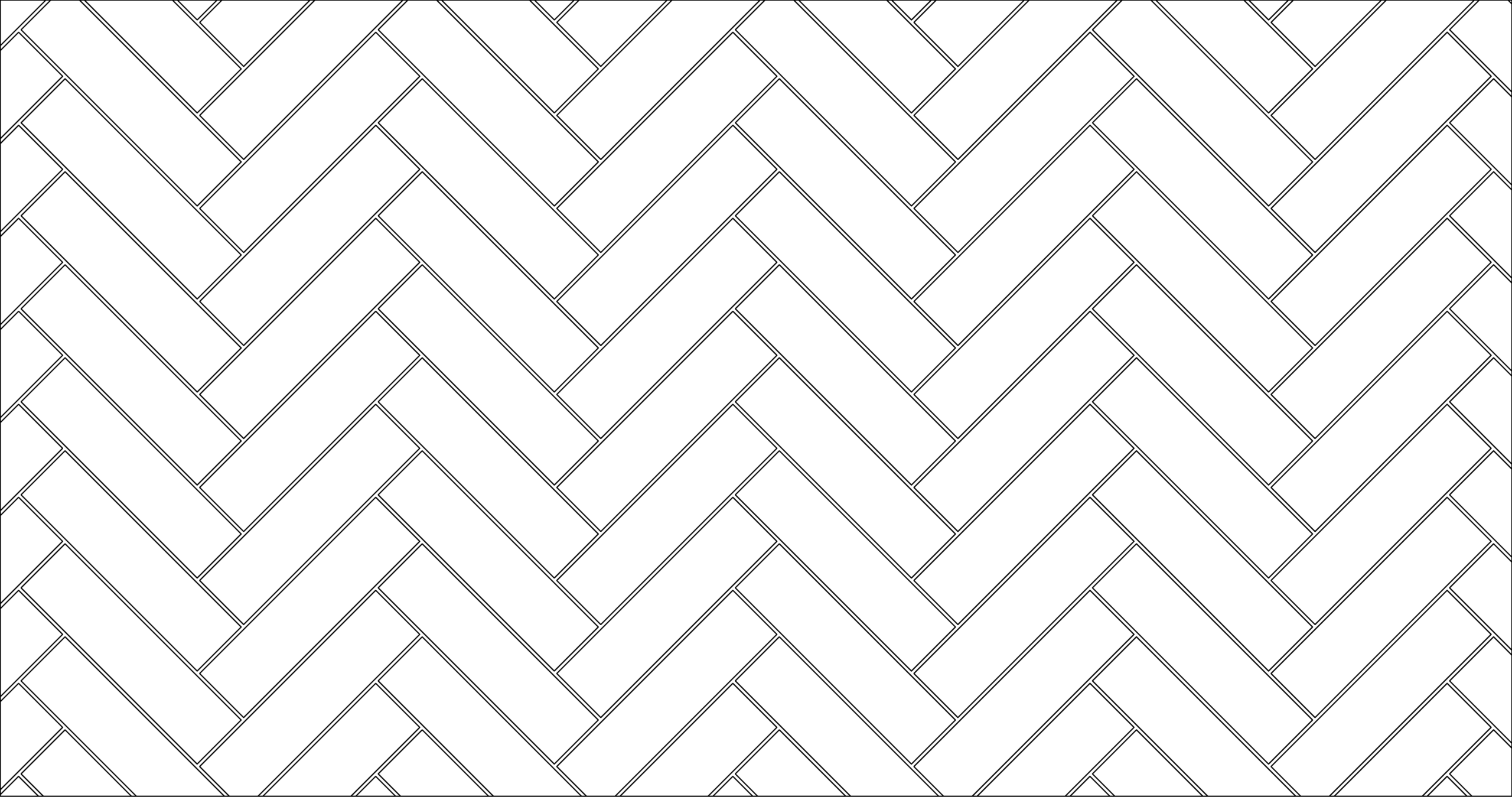

Patterns

Running Bond

Stacked Bond

Basket Weave

Full Herringbone

Split Herringbone

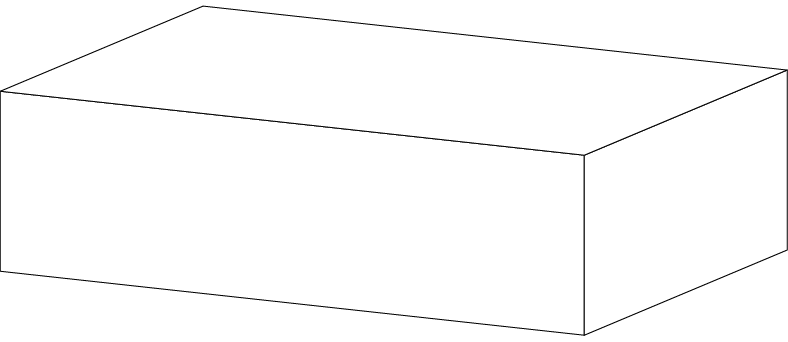

Firebrick Sizes

Full

Buff

9" (L) x 4" (W) x 2 1/2" (D)

Red

9" (L) x 4 1/2" (W) x 2 1/2" (D)

Black (Glazed)

9" (L) x 4 1/2" (W) x 2 1/2" (D)

Black (Unglazed)

9" (L) x 4 1/2" (W) x 2 1/2" (D)

Slate Gray

9" (L) x 4 1/2" (W) x 2 1/2" (D)

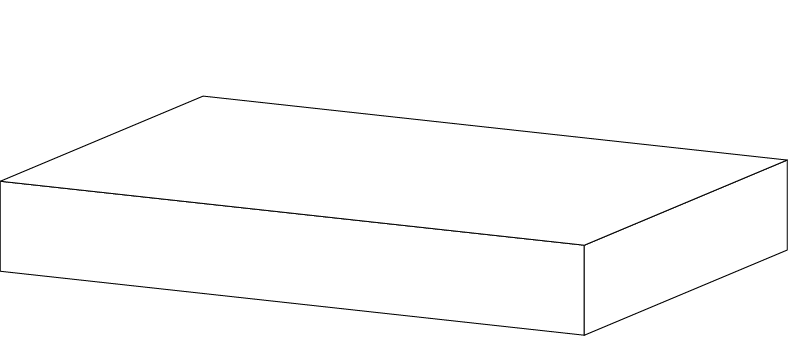

Split

Buff

9" (L) x 4" (W) x 1 1/4" (D)

Red

9" (L) x 4 1/2" (W) 1 1/4" (D)

Black (Glazed)

9" (L) x 4 1/2" (W) 1 1/4" (D)

Black (Unglazed)

9" (L) x 4 1/2" (W) 1 1/4" (D)

Slate Gray

9" (L) x 4 1/2" (W) 1 1/4" (D)

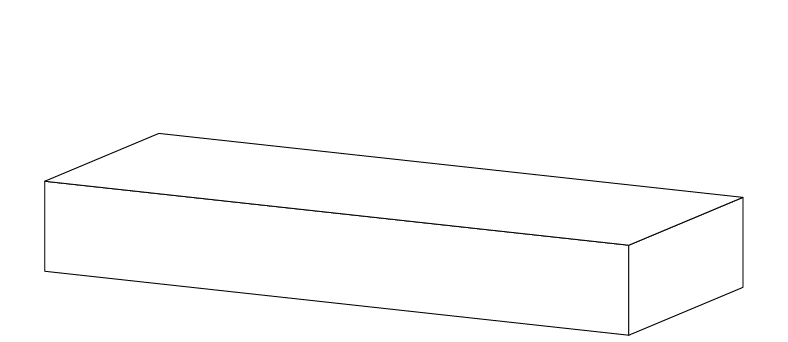

Soap

Buff

9" (L) x 2 1/4" (W) x 1 1/4" (D)

Red

9" (L) x 2 1/4" (W) x 1 1/4" (D)

Black (Glazed)

N/A

Black (Unglazed)

N/A

Slate Gray

N/A